In a dynamic business world, we are constantly evolving and introducing a range of technological innovations. Our continuous development is the result of a great passion for creating ergonomic, functional and timeless furniture that not only meets today’s needs but also defines the standards of the future.

The future is in our hands...

All the values that define our brand and make up the foundations of Bejot are deeply rooted in our DNA. We have always focused on quality and durable products and ergonomic solutions. Although furniture is our priority, we pay just as much attention to caring for the environment, constant development and implementation of new technologies, as well as creating the right conditions for employees. We have been observing changes in the working environment for years - we try not only to adjust to them, but above all to create, inspire, listen to needs and stay ahead of trends. We are optimising management and its processes, building a new system warehouse, doubling production capacity, implementing plans, making dreams come true!

…and tomorrow starts today

Bejot’s development focuses on increasing efficiency at every stage of product manufacturing - from design and production chain to customer service and product delivery. The new system warehouse under construction will allow us to store and manage products in accordance with the organisational system we have developed. This will optimise the flow of goods, maximise the use of storage space, as well as automate systems and speed up individual tasks, which is crucial in a dynamic logistics and production environment. By investing in modern solutions and technologies, we can significantly increase our operational efficiency and reduce the risk of errors. We also have the opportunity to benefit from even more meticulous system documentation, which allows us to control stock levels and analyse sales and inventory management data.

Our plans for 2024–2025

3D laser for metal profiles

The 3D laser allows an even more precise adjustment of the parts to be cut, reducing subsequent welding and grinding processes to a minimum. It reduces machine downtime to zero by automatically configuring the next production run. At the end of each batch, it will automatically adjust to the new section without interrupting the production cycle.

large-size foam injection moulding machine

This machine will allow the efficient production of large and durable foam parts. Using the large-size foam injection moulding machine, it will be possible to mould an entire sofa (up to 15 kg), reducing the number of processes, CO2 emissions and waste, as well as reducing packaging and extending the service life of the product.

new packaging line for large-size products

The implementation of a new packaging line for large-size products will aim to introduce a number of benefits that will cover both the production process and the logistics. Through optimisation, we will minimise the quantity, size and shape of the packaging used, which will contribute to more efficient transport and storage, and reduce costs.

system warehouse

In 2024, our new system warehouse using advanced technologies such as RFID systems, barcodes and real-time stock monitoring software will be commissioned. It will enable rapid response to changes in demand or supply, while narrow aisles and high storage will translate into excellent space optimisation. In addition, the collection of data on warehouse operations will facilitate analysis and management decisions.

TIG and MIG welding robot

TIG and MIG welding using robots will result in precision, high weld quality, increased productivity, time and cost savings and reduced gas consumption. In both cases, welding will not require grinding, so there will be no dust floating from everywhere. This will contribute to the safety of workers, especially when working in areas requiring precision and geometric accuracy.

laser edge banding machine

The quality, as well as the visual and aesthetic aspect of the furniture, will be enhanced by the new technology of seamless edge banding of narrow edges. This method does not require the use of glue, but allows a water-resistant and high-quality finish to be achieved.

automation in the flow between production processes

The ETON material handling system is a state-of-the-art solution used in large sewing plants all over the world to move components between the cutting room, the sewing station and the warehouse. ETON will streamline our daily work and make it easier to manage the various stages of production.

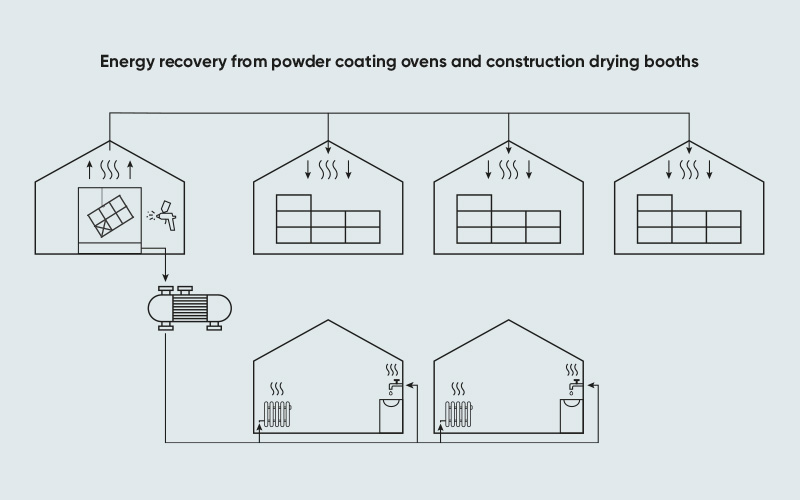

recovery of generated heat

We are currently recovering energy from the powder coating ovens and the construction drying booth. We use it to heat three facilities, two office buildings and domestic hot water. The efficient use of heat generated by the painting processes contributes to minimising the ecological footprint, in line with our commitment to environmental action. In the near future, we plan to expand the use of the heat recovered from the paint shop. We want to use it to additionally heat our showroom and one of our office buildings, which will further optimise our heat consumption.

|

DE

DE

PL

PL

EN

EN

FR

FR