epocc | conference chairs

comfort is in the detail

The ergonomic design together with the retention of the wide seat allows maximum seating comfort while maintaining a classic and stylish form.

stylish armrests

Complementing the standard form of the chair are armrests. They are available in two options of polyurethane pads ( PU or PUT)

easy mobility

A special handle at the back of the backrest allows the chair to be easily moved to any location.

Configurator

To find out the price of the configured product, please:

1. Download the PDF (click )

2. Send it to export@bejot.eu

Specification

Technical data

| Base | ||

| Powder painted (colors according to the Bejot pattern book) | ● | |

| EP 215 - Chrome | ○ | |

| EP 220 - Chrome | ○ | |

| EP 220P - Chrome | ○ |

| Feet | CODE | |

| Spherical feet | TK | ● |

| Base | ||

| Powder painted (colors according to the Bejot pattern book) | ● | |

| EP 215 - Chrome | ○ | |

| EP 220 - Chrome | ○ | |

| EP 220P - Chrome | ○ |

| Armpads on the armrests | CODE | |

| Soft, black polyurethane - PU | PU | ● |

| Black polyurethane - PU type tube | PUT | ○ |

| Feet | CODE | |

| Spherical feet | TK | ● |

● Standard ○ Option

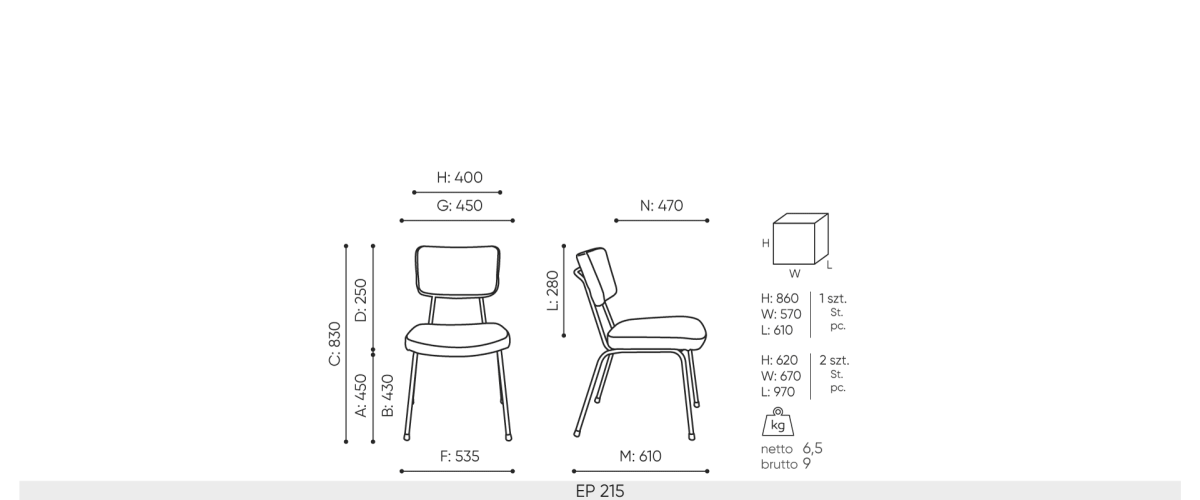

Dimensions

| A | seat height: overall dimensions |

| B | seat height: measured according to the norm PN EN 1335-1 with a load of 640N |

| C | chair height adjustment |

| D | backrest height adjustment |

| E | headrest height adjustment |

| F | dimensional width chair / ø base |

| G | seat width |

| H | backrest width |

| I | width between armrests |

| K | height from the floor to the armrest |

| L | backrest lenght |

| M | dimensional chair depth |

| N | seat depth adjustment / seat lenght |

All dimensions are in [mm] and refer to basic version products. The indicated dimensions can change depending on the selected equipment package. Bejot reserves the right to change selected elements and this may slightly affect the product’s dimensions. In case of any special requirements on dimensions of a given product, the afore-mentioned information should be acknowledged by the Producer. The specification does not constitute an offer within the meaning of the Civil Code. Dimensions and weights are approximate and may vary by 5%. The requirements of the standard are always met.

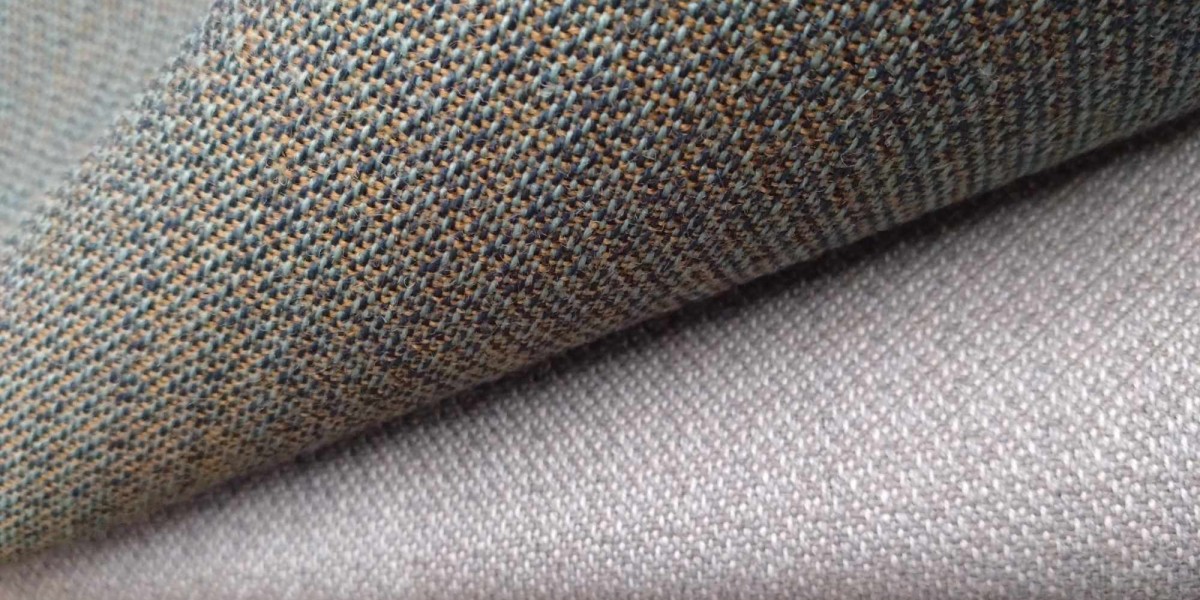

Sampler

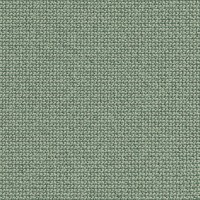

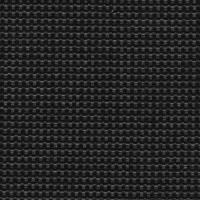

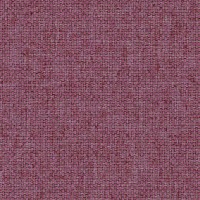

Bond

Durable polyester fabric with a uniform color, resistant to abrasion. It is certified in accordance with the EN 1021-2 standard for the flammability of upholstered furniture, having passed tests with two ignition sources: a smoldering cigarette and a match flame.

It features a distinct and dense weave that creates a clearly visible texture. It drapes very well on furniture and is suitable for use both in offices and at home.

Composition: Polyester 100%, Weight 250 g/m2 +/-5%, Abrasion Resistance 100 000 Martindale cycles (EN ISO 12947-2), Pilling 5 (EN ISO 12945-2), Light Fastness 6 (EN ISO 105-B02), Flammability (BS EN 1021-1) (BS EN 1021-2), CRIB 5

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

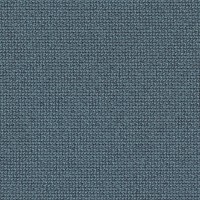

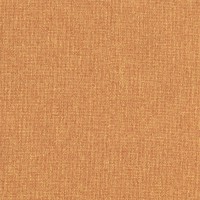

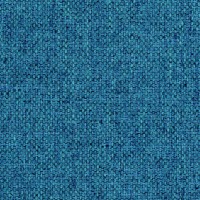

Fenno

A fabric with high abrasion resistance and an Oeko-Tex certification, confirming that the product is harmless to humans. It passes the BS 5852-0 furniture flammability test according to the British standard, which simulates ignition from a match equivalent.

The fabric’s surface resembles wool felt, is soft to the touch, and is additionally coated with a protective finish that guards against liquid stains.

100% Polyester , weight 402g/m2, Abrasion Resistance 100 000 Martindale cycles (EN ISO 12947-2), Pilling 4 (EN ISO 12945-2), Light fastness 5 (EN ISO 105-B02:2014), Fastness to Rubbing wet 4-5, dry 4-5 (EN ISO 105-X12) Flamability (BS 5852 Ignition Source 0, water repellent , Oekotex

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

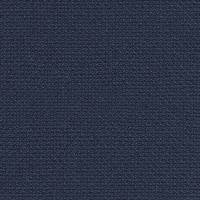

Keimo

Artificial leather with a gently embossed polyurethane coating and high abrasion resistance. It passes the BS 5852-0 furniture flammability test according to the British standard, which simulates ignition from a match equivalent.

Available in 18 universal colors. For lighter shades, color migration from other materials—such as denim—may occur.

Composition: surface 100% PU,basic material: 65% polyester, 35% cotton, weight 435 g/m2 +/-5%, abrasion >100 000 Martindale cycles (EN ISO 5470-2 method 1), light fastness >5(EN ISO 105 B 02), resistance to pilling 4-5 (EN ISO 105-X12), non- flammability certificat (BS 5852/DIN EN 1021-1)

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

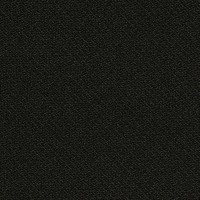

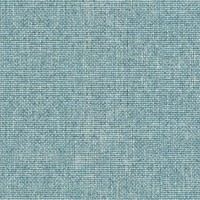

Lodge

Lodge is an elegant and durable fabric designed with modern interiors in mind. Made of 100% polyester, it combines irregular bouclé yarn with smooth fibers, giving it depth and an intriguing texture. The fabric captivates with its contrasting, expressive coloration, adding character to any design. Available in a palette of 10 carefully selected colors that perfectly reflect current interior design trends.

Composition: 100% polyester, weight 402g/m2, Abrasion resistance 100 000 Martindale cycles (EN ISO 12947-2), Pilling 4 (EN ISO 12945-2), Light fastness 5 (EN ISO 105-B02:2014), Fastness to rubbing 5, dry 4-5, wet 5 (EN ISO 105-X12) Flammability BS 5852 Ignition Source 0, Oekotex

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

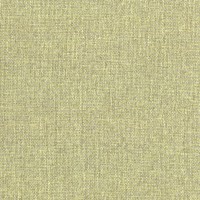

Sawana

Sawana is a product with high abrasion resistance and an Oeko-Tex certification, confirming the product is safe for human use.

It is a polyester fabric with a subtle sheen, characterized by a smooth surface and a gently melange (blended) color.

Composition 100% polyester, weight 245g/m2 ± 5%, roll width 140 cm, abrasion resistance 70,000 Martindale cycles (BS EN ISO 12947-2:1999), pilling 4-5 (DIN EN ISO 12945/2:2000), light fastness 4 (EN ISO 105-B02:2013), fastness to rubbing wet: 4 (UNI EN ISO 105-X12:2016) dry: 4-5 (UNI EN ISO 105-X12:2016), flammability -DIN EN 1021-1

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Alaska

Alaska is a unique polyester fabric featuring melange, nuanced colors. The combination of multicolored yarns into a single bouclé thread creates an intriguing visual effect, giving the material depth and a distinctive character.

Excellent technical performance and a FibreGuard finish—designed to simplify cleaning—ensure that Alaska maintains its appearance and quality for years.

FibreGuard is an innovative technology that merges stain-free protection with elegant, high-quality upholstery fabrics. It offers easy cleaning, low maintenance costs, and long-lasting aesthetic appeal.

Composition 51% recycled polyester, 49% polyester, Weight 578 g/m2 ± 5%, abrasion resistance 40 000 Martindale cycles (EN ISO 12947-2), Pilling 4 (EN ISO 12945-2), Light fastness 6 (EN ISO 105-B02), Fastness to rubbing Wet: 4-5 (EN ISO 105-X12) Dry: 4-5 (EN ISO 105-X12), Flammability BS 5852-0, Oekotex, FibreGuard

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Alpa

Bouclé fabric with large, irregular loops, combining a distinctive texture with natural colors. Soft and pleasant to the touch, it creates a cozy atmosphere in interiors. It is Oeko-Tex certified, confirming its safety.

Composition: 95% Polyester, 5% Acrylic, Weight 550 g/m2 ± 5%, Roll width 140 cm, Abrasion resistance >50 000 cykli Martindale’a (EN ISO 12947-2), Pilling 4 (UNI EN ISO 12945-2), Light fastness 4 (EN ISO 105-B02), Fastness to rubbing Wet: 4-5 (ISO 105-X12), Dry: 4-5 (ISO 105-X12)

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Charles

Charles is an upholstery fabric with a velvety surface, featuring high abrasion resistance (90,000 Martindale cycles). It is available in a wide range of colors, from warm reds and browns to cool blues and greys. Due to its structure (long pile), Charles may develop characteristic shading patterns during use, typical of velour fabrics, creating the appearance of varying tones in the upholstery. It is also susceptible to the so-called "seating effect," so it should be brushed very gently to maintain its appearance.

Composition: 100% Polyester Weight: 290 g/m2 Roll width: 140cm Abrasion Resistance 90,000 Martindale cycles (BS EN ISO 12947-2:1998) Pilling: 4 (EN ISO 12 945-2) Light Fastness 5 (ISO 105-B02) Fastness to Rubbing Wet: 4-5 (UNI EN ISO 105-X12) Dry: 4-5 (UNI EN ISO 105-X12) Flammability: -DIN EN 1021-1

Charles fabric, due to its structure (long hair), can be arranged in a velour way while being used, creating the impression of different shades of upholstery. It is also susceptible to bending while sitting, which is why it should be combed very gently.

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Charles - Studio Design

Charles is an upholstery fabric with a velvety surface, featuring high abrasion resistance (90,000 Martindale cycles). It is available in a wide range of colors, from warm reds and browns to cool blues and greys.

Due to its structure (long pile), Charles may develop characteristic shading patterns during use, typical of velour fabrics, creating the appearance of varying tones in the upholstery. It is also susceptible to the so-called "seating effect," so it should be brushed very gently to maintain its appearance.

*Studio Design - Extended delivery time

Composition: 100% Polyester Weight: 290 g/m2 Roll width: 140cm Abrasion Resistance 90,000 Martindale cycles (BS EN ISO 12947-2:1998) Pilling: 4 (EN ISO 12 945-2) Light Fastness 5 (ISO 105-B02) Fastness to Rubbing Wet: 4-5 (UNI EN ISO 105-X12) Dry: 4-5 (UNI EN ISO 105-X12) Flammability: -DIN EN 1021-1

Charles fabric, due to its structure (long hair), can be arranged in a velour way while being used, creating the impression of different shades of upholstery. It is also susceptible to bending while sitting, which is why it should be combed very gently.

Studio Design - Extended delivery time

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Cura

Cura is a versatile, two-tone upholstery fabric by Gabriel, made from 100% recycled polyester, which is itself recyclable. It holds the Oeko-Tex certification, confirming its safety.

The fabric features a matte, mélange texture that mimics the look of natural fibers, along with a trendy color palette characterized by subtle saturation and soft, blurred hues.

Composition: 98% recycled polyester, 2% polyester, Weight: 300 g/m² ± 5%, Abrasion resistance: 100,000 Martindale cycles (EN ISO 12947-2), Pilling: 4–5 (EN ISO 12945-2), Lightfastness: 5–8 (EN ISO 105-B02:2014)

Rubbing fastness: wet 4–5, dry 4–5 (EN ISO 105-X12), Flammability BS EN 1021-1, BS EN 1021-2, Certifications: EU Ecolabel, Oeko-Tex

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

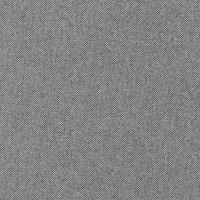

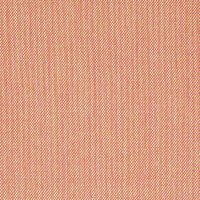

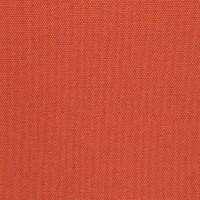

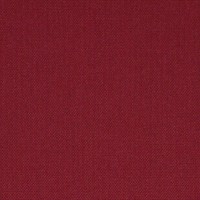

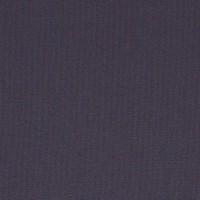

Era - Studio Design

This product by Camira is a polyester fabric featuring a mélange herringbone pattern and high abrasion resistance (100,000 Martindale cycles). The color palette includes both bright, cheerful tones and more subdued shades. Its matte texture and wide range of colors make it an appealing and versatile choice.

*Studio Design - Extended delivery time

Composition: Polyester 100%, Weight: 320g/m2 ±5%, Abrasion Resistance 100 000 Martindale cycles (EN ISO 12947:1998), Fastness to Rubbing 4 (ISO 105-X12:2002), Light Fastness 5 (EN ISO 105-B02:2014), Flammability (BS EN 1021-1 / BS EN 1021-2 / BS7176:2007 Low Hazard)

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Pastel

Flame-retardant base fabric made from Trevira CS yarn

A high-quality fabric made from original flame-retardant Trevira CS polyester yarn (100% polyester), meeting the highest fire safety standards. It is certified by Oeko-Tex, ensuring it is free from harmful substances and safe for use.

Available in a range of classic colours, the fabric offers exceptional durability – with an abrasion resistance of 70,000 Martindale cycles, it is a perfect choice for high-traffic commercial and public interiors.

Composition: Polyester 100%- TREVIRA CS,weight 260g/m2 +/-5%, abrasion 70 000 Martindale cycles, resistance to 5 (EN ISO 12945), light fastness 6 (EN ISO 105-B02), non-flammbility certificate (EN 1021-1, EN 1021-2; Crib 5; BS 7176 Medium Hazard;

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Roccia

Roccia is a fabric by Fidivi, made from original flame-retardant Trevira CS polyester yarn, ensuring the highest standards of fire resistance. It is Oeko-Tex certified, confirming its safety for human health. The fabric features a matte, natural-feeling surface. Available in a variety of appealing colors, it boasts high abrasion resistance (70,000 Martindale cycles) and excellent lightfastness.

100% polyester-TREVIRA CS weight 250g/m2 +/-5%, abrasion 70 000 Martindale cycles (UNI EN ISO 12947/2), resistance to pilling 5 (EN ISO 12945/2), light fastness 6 (EN ISO 105-B02),fastness to rubbing wet:4 (UNI EN ISO 105-X12) dry:5 (UNI EN ISO 105-X12), non-flammbility certificate: EN 1021-1:2006 EN 1021-2:2006

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Ally

A product by Svensson, made from Norwegian sheep wool blended with polyamide, combines raw Scandinavian design with a rich palette of mélange colors. Natural shades dominate, and when mixed with dyed fibers, they create a sense of depth in the texture. The diagonal weave highlights the refined character of the wool.

The fabric is highly abrasion-resistant and Oeko-Tex certified, making it suitable for a wide range of interior applications.

Composition 85% Wool, 15% Polyamid, Weight 320 g/m2 ± 5%, Abrasion resistance 100 000 Martindale cycles (EN ISO 12947-2), Light fastness 5-7 (EN ISO 105-B02), Fastness to rubbing Wet: 3-4 (EN ISO 105-X12), Dry: 4 (EN ISO 105-X12), Flammability • EN 1021-1 • EN 1021-2

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Ally-Studio Design

A product by Svensson, made from Norwegian sheep wool blended with polyamide, combines raw Scandinavian design with a rich palette of mélange colors. Natural shades dominate, and when mixed with dyed fibers, they create a sense of depth in the texture. The diagonal weave highlights the refined character of the wool.

The fabric is highly abrasion-resistant and Oeko-Tex certified, making it suitable for a wide range of interior applications.

*Studio Design - Extended delivery time

Composition 85% Wool, 15% Polyamid, Weight 320 g/m2 ± 5%, Abrasion resistance 100 000 Martindale cycles (EN ISO 12947-2), Light fastness 5-7 (EN ISO 105-B02), Fastness to rubbing Wet: 3-4 (EN ISO 105-X12), Dry: 4 (EN ISO 105-X12), Flammability • EN 1021-1 • EN 1021-2

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Alpa-Studio Design

Bouclé fabric with large, irregular loops, combining a distinctive texture with natural colors. Soft and pleasant to the touch, it creates a cozy atmosphere in interiors. It is Oeko-Tex certified, confirming its safety.

*Studio Design - Extended delivery time

Composition: 95% Polyester, 5% Acrylic, Weight 550 g/m2 ± 5%, Roll width 140 cm, Abrasion resistance >50 000 cykli Martindale’a (EN ISO 12947-2), Pilling 4 (UNI EN ISO 12945-2), Light fastness 4 (EN ISO 105-B02), Fastness to rubbing Wet: 4-5 (ISO 105-X12), Dry: 4-5 (ISO 105-X12)

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Blazer

This product from Camira is a fabric made of 100% premium-quality wool – durable and refined. It is produced through a process of weaving, felting, and surface raising. Naturally flame-retardant, it meets the cigarette and match ignition tests according to British standards.

It comes with a 10-year warranty and an abrasion resistance of 45,000 Martindale cycles.

Available in a wide palette of shades, ranging from natural beiges and browns to vibrant floral tones. Wool is naturally stain-resistant, repels water, and maintains its aesthetic appearance with proper care.

Virgin wool 100%, Weight 460g/m2 +/-5%, abrasion resistance 65 000 Martindale cycles, fastness to pilling 4 (BS:EN ISO 12945-2:2000), ligh fastness 5 (ISO 105-B02:1999); non-flammability certificate: BS EN 1021-1:2006, BS EN 1021-2:2006,

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Cura - Studio Design

Cura is a versatile, two-tone upholstery fabric by Gabriel, made from 100% recycled polyester, which is itself recyclable. It holds the Oeko-Tex certification, confirming its safety.

The fabric features a matte, mélange texture that mimics the look of natural fibers, along with a trendy color palette characterized by subtle saturation and soft, blurred hues.

*Studio Design - Extended delivery time

Composition: 98% recycled polyester, 2% polyester, Weight: 300 g/m² ± 5%, Abrasion resistance: 100,000 Martindale cycles (EN ISO 12947-2), Pilling: 4–5 (EN ISO 12945-2), Lightfastness: 5–8 (EN ISO 105-B02:2014)

Rubbing fastness: wet 4–5, dry 4–5 (EN ISO 105-X12), Flammability BS EN 1021-1, BS EN 1021-2, Certifications: EU Ecolabel, Oeko-Tex

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Cyber-Studio Design

Cyber is a fabric that catches the eye and sparks inspiration. Made from 100% recycled polyester, it combines environmental responsibility with modern design. Its multidimensional texture, matte finish, and subtle suede-like softness give interiors a warm, natural feel.

Unique, bold color combinations make Cyber a perfect fit for creative, flexible workspaces — where both aesthetics and functionality matter.

100% recycled polyester Möbelfakta certification – a guarantee of quality and responsible production

Studio Design – extended order lead time

Composition: 100% post-consumer recycled polyester, Weight: 407 g/m², Abrasion resistance: 120,000 Martindale cycles (EN ISO 12947)

Pilling resistance: 4–5 (EN ISO 12945-2) Lightfastness: 7–8 (ISO 105-B02) Color fastness to rubbing: Wet: 4–5 Dry: 4–5 (ISO 105-X12) Flame retardancy certification: BS EN 1021-1 & 2 (cigarette and match tests)

Certified: Oeko-Tex

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Easy - Studio Design

Easy is a beautiful, monochromatic upholstery fabric with a subtle diagonal weave structure, created by Svensson. Its rich, fruit- and flower-inspired colours highlight the natural beauty of wool.

Thanks to its high abrasion resistance and Oeko-Tex certification, the fabric is suitable for a wide range of interior applications. It is part of the Studio Design collection, which may result in extended lead times for orders.

*Studio Design - Extended delivery time

Composition: Wool 85% Polyamide 15%, weight: 330 g/m², abrasion resistance 150 000 Martindale cycles (EN ISO 12947-2), light fastness 5-7 (EN ISO 105-B02), fastness to rubbing wet:3-4, dry:4 (EN ISO 105-X12), flammability : EN 1021-1&2, BS 5852 crib 5, Oekotex

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Oceanic

Oceanic is a unique fabric by Camira, made entirely from recycled polyester, 50% of which is SEAQUAL® yarn derived from marine waste. It’s an eco-friendly choice for seat upholstery.

The fabric is Oeko-Tex certified, confirming its safety. With high abrasion resistance and a 10-year manufacturer’s warranty, it is an excellent sustainable option for your furniture.

Composition 100% post-consumer recycled polyester (including 50% Sequal yam), Weight 497 g/m2 ± 5%, Abrasion resistance 100 000 Martindale cycles (EN ISO 12947-2), Light fastness 4-5 (EN ISO 105-B02), Fastness to rubbing Wet: 4 (EN ISO 105-X12) Dry: 4 (ENbISO 105-X12), Flammability • BS EN 1021-1:2014 • BS EN 1021-2:2014 • BS 7176 (Low Hazard)

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Silvertex

Silvertex is an exceptionally durable textile material with a PVC coating, offered by Spradling, featuring the innovative PERMABLOK finish. This technology helps create a more hygienic environment by reducing the presence of bacteria, fungi, and mildew — particularly important in medical and hospitality settings.

The material is highly resistant to cracking, tearing, and loss of elasticity.

Available in a wide range of colours, its semi-matte surface, embossed with a fabric-like texture, makes it an outstanding choice for use in public interiors. Despite its high level of protection, lighter shades may be prone to staining due to colour migration from other textiles.

Surface-100% Vinyl, basic material - 100% Polyester Hi-Loft2, weight 685g/m2, abrasion 300 000 Martindale cycles (EN ISO 12947:1999 Part 2), light fastness >7, non-flammability certificate (BS EN 1021-1/2, EN 1021/2, EN 71-2,

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Silvertex - Studio Design

Silvertex is an exceptionally durable textile material with a PVC coating, offered by Spradling, featuring the innovative PERMABLOK finish. This technology helps create a more hygienic environment by reducing the presence of bacteria, fungi, and mildew — particularly important in medical and hospitality settings.

The material is highly resistant to cracking, tearing, and loss of elasticity.

Available in a wide range of colours, its semi-matte surface, embossed with a fabric-like texture, makes it an outstanding choice for use in public interiors. Despite its high level of protection, lighter shades may be prone to staining due to colour migration from other textiles.

*Studio Design - Extended delivery time

Surface-100% Vinyl, basic material - 100% Polyester Hi-Loft2, weight 685g/m2, abrasion 300 000 Martindale cycles (EN ISO 12947:1999 Part 2), light fastness >7, non-flammability certificate (BS EN 1021-1/2

Studio Design - Extended delivery time

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Synergy

Synergy is a fabric by Camira, made of 95% premium-quality sheep’s wool with the addition of polyamide. It is produced through weaving, gentle felting, and surface raising, which gives it a soft and refined texture.

Compared to other fibres, wool is exceptionally resistant to soiling, naturally repels water, and with proper care maintains stain resistance, helping it retain its aesthetic appearance for longer. It is a strong, versatile fibre that creates durable and elegant textiles.

Compostion:virgin wool 95%, polyamide 5%; Weight: 400g/m2 ±5% Abrasion Resistance > 100 000 Martindale cycles, Fastness to Rubbing: 4 (ISO 105-X12) Light Fastness: 5 (ISO 105-B02) Flammability: EN 1021-1&2 Cigarette & Match

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Synergy - Studio Design

Synergy is a fabric by Camira, made of 95% premium-quality sheep’s wool with the addition of polyamide. It is produced through weaving, gentle felting, and surface raising, which gives it a soft and refined texture.

Compared to other fibres, wool is exceptionally resistant to soiling, naturally repels water, and with proper care maintains stain resistance, helping it retain its aesthetic appearance for longer. It is a strong, versatile fibre that creates durable and elegant textiles.

*Studio Design - Extended delivery time

Compostion:virgin wool 95%, polyamide 5%; Weight: 400g/m2 ±5% Abrasion Resistance > 100 000 Martindale cycles, Fastness to Rubbing: 4 (ISO 105-X12) Light Fastness: 5 (ISO 105-B02) Flammability: EN 1021-1&2 Cigarette & Match

Studio Design - Extended delivery time

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Oceanic-Studio Design

Oceanic is a unique fabric by Camira, made entirely from recycled polyester, 50% of which is SEAQUAL® yarn derived from marine waste. It’s an eco-friendly choice for seat upholstery.

The fabric is Oeko-Tex certified, confirming its safety. With high abrasion resistance and a 10-year manufacturer’s warranty, it is an excellent sustainable option for your furniture.

*Studio Design - Extended delivery time

Composition: 100 % recycled polyester, weight 497g/m2 +/-5%, width 140cm, Abrasion resistance: ≥100 000 Martindale cycles, light fastness: 4/5 (EN ISO 105-B02), fastness to rubbing: wet: 4 (EN ISO 105-X12) dry:4 (EN ISO 105-X12) Flammability: EN 1021-1&2, BS 7176 Low Hazard; Oekotex

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Remix - Studio Design

This fabric is from Kvadrat, a company committed to quality and sourcing the finest yarns from New Zealand, Australia, the UK, and Norway. Wool is a natural, renewable material whose fibres have inherent flame resistance – it ignites at high temperatures and chars when exposed to fire, rather than melting or dripping.

Compared to other fibres, wool is especially resistant to soiling, naturally repels water, and with proper care maintains stain resistance, preserving its aesthetic appearance over time. It is a versatile, strong fibre that creates durable textiles which age gracefully.

The fabric is part of the Studio Design collection, which may result in extended lead times for orders.

*Studio Design - Extended delivery time

Composition: 90% wool, 10% nylon Weight: ok 300 g/m2 Abrasion Resistance: 100 000 Martindale cycles, Pilling: 3-4 (EN ISO 12945-2:2000) Light Fastness: 5-7 (ISO 105-B02:2000) Flammability: EN 1021 - 1/2 Producer: kvadrat Denmark

Studio Design - Extended delivery time

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Steelcut Trio 3-Studio Design

This fabric by Kvadrat places strong emphasis on quality and the origin of its yarns, sourced from New Zealand, Australia, the United Kingdom, and Norway. It is distinguished by exceptional durability and rich color depth. The innovative three-dimensional structure of the fabric creates an intriguing surface texture.

Its extensive color palette offers new possibilities for combining deep shades of red, purple, and green, as well as a variety of midtones that harmoniously blend vibrant floral hues with natural tones.

*Studio Design - Extended delivery time

Composition: 90% wool, 10% nylon; Abrasion Resistance 100 000 Martindale cycles; Fastness to Rubbing 3-4 (EN ISO 12945); Light Fastness: 5-7 (ISO 105-B02) Flammability: EN 1021-1/2; BS 5852 part 1

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Size Ca.5m2, thickness >0,8mm-1,1mm, wet rub tests>250 (BS EN ISO 11640: 1998) dry rub tests >500 (EN ISO 11640:1998) flex resistance > 50 000 cycles (BS EN ISO 5402:2002), PCP und CFC used during tanning proces, natural colour varations may occur, non-flammability certyficate (UNI EN 1021-1:2006, UNI EN 1021-2:2006)

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Metal - powder coated

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Bond

Durable polyester fabric with a uniform color, resistant to abrasion. It is certified in accordance with the EN 1021-2 standard for the flammability of upholstered furniture, having passed tests with two ignition sources: a smoldering cigarette and a match flame.

It features a distinct and dense weave that creates a clearly visible texture. It drapes very well on furniture and is suitable for use both in offices and at home.

Composition: Polyester 100%, Weight 250 g/m2 +/-5%, Abrasion Resistance 100 000 Martindale cycles (EN ISO 12947-2), Pilling 5 (EN ISO 12945-2), Light Fastness 6 (EN ISO 105-B02), Flammability (BS EN 1021-1) (BS EN 1021-2), CRIB 5

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Fenno

A fabric with high abrasion resistance and an Oeko-Tex certification, confirming that the product is harmless to humans. It passes the BS 5852-0 furniture flammability test according to the British standard, which simulates ignition from a match equivalent.

The fabric’s surface resembles wool felt, is soft to the touch, and is additionally coated with a protective finish that guards against liquid stains.

100% Polyester , weight 402g/m2, Abrasion Resistance 100 000 Martindale cycles (EN ISO 12947-2), Pilling 4 (EN ISO 12945-2), Light fastness 5 (EN ISO 105-B02:2014), Fastness to Rubbing wet 4-5, dry 4-5 (EN ISO 105-X12) Flamability (BS 5852 Ignition Source 0, water repellent , Oekotex

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Keimo

Artificial leather with a gently embossed polyurethane coating and high abrasion resistance. It passes the BS 5852-0 furniture flammability test according to the British standard, which simulates ignition from a match equivalent.

Available in 18 universal colors. For lighter shades, color migration from other materials—such as denim—may occur.

Composition: surface 100% PU,basic material: 65% polyester, 35% cotton, weight 435 g/m2 +/-5%, abrasion >100 000 Martindale cycles (EN ISO 5470-2 method 1), light fastness >5(EN ISO 105 B 02), resistance to pilling 4-5 (EN ISO 105-X12), non- flammability certificat (BS 5852/DIN EN 1021-1)

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Lodge

Lodge is an elegant and durable fabric designed with modern interiors in mind. Made of 100% polyester, it combines irregular bouclé yarn with smooth fibers, giving it depth and an intriguing texture. The fabric captivates with its contrasting, expressive coloration, adding character to any design. Available in a palette of 10 carefully selected colors that perfectly reflect current interior design trends.

Composition: 100% polyester, weight 402g/m2, Abrasion resistance 100 000 Martindale cycles (EN ISO 12947-2), Pilling 4 (EN ISO 12945-2), Light fastness 5 (EN ISO 105-B02:2014), Fastness to rubbing 5, dry 4-5, wet 5 (EN ISO 105-X12) Flammability BS 5852 Ignition Source 0, Oekotex

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Sawana

Sawana is a product with high abrasion resistance and an Oeko-Tex certification, confirming the product is safe for human use.

It is a polyester fabric with a subtle sheen, characterized by a smooth surface and a gently melange (blended) color.

Composition 100% polyester, weight 245g/m2 ± 5%, roll width 140 cm, abrasion resistance 70,000 Martindale cycles (BS EN ISO 12947-2:1999), pilling 4-5 (DIN EN ISO 12945/2:2000), light fastness 4 (EN ISO 105-B02:2013), fastness to rubbing wet: 4 (UNI EN ISO 105-X12:2016) dry: 4-5 (UNI EN ISO 105-X12:2016), flammability -DIN EN 1021-1

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Alaska

Alaska is a unique polyester fabric featuring melange, nuanced colors. The combination of multicolored yarns into a single bouclé thread creates an intriguing visual effect, giving the material depth and a distinctive character.

Excellent technical performance and a FibreGuard finish—designed to simplify cleaning—ensure that Alaska maintains its appearance and quality for years.

FibreGuard is an innovative technology that merges stain-free protection with elegant, high-quality upholstery fabrics. It offers easy cleaning, low maintenance costs, and long-lasting aesthetic appeal.

Composition 51% recycled polyester, 49% polyester, Weight 578 g/m2 ± 5%, abrasion resistance 40 000 Martindale cycles (EN ISO 12947-2), Pilling 4 (EN ISO 12945-2), Light fastness 6 (EN ISO 105-B02), Fastness to rubbing Wet: 4-5 (EN ISO 105-X12) Dry: 4-5 (EN ISO 105-X12), Flammability BS 5852-0, Oekotex, FibreGuard

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Alpa

Bouclé fabric with large, irregular loops, combining a distinctive texture with natural colors. Soft and pleasant to the touch, it creates a cozy atmosphere in interiors. It is Oeko-Tex certified, confirming its safety.

Composition: 95% Polyester, 5% Acrylic, Weight 550 g/m2 ± 5%, Roll width 140 cm, Abrasion resistance >50 000 cykli Martindale’a (EN ISO 12947-2), Pilling 4 (UNI EN ISO 12945-2), Light fastness 4 (EN ISO 105-B02), Fastness to rubbing Wet: 4-5 (ISO 105-X12), Dry: 4-5 (ISO 105-X12)

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Charles

Charles is an upholstery fabric with a velvety surface, featuring high abrasion resistance (90,000 Martindale cycles). It is available in a wide range of colors, from warm reds and browns to cool blues and greys. Due to its structure (long pile), Charles may develop characteristic shading patterns during use, typical of velour fabrics, creating the appearance of varying tones in the upholstery. It is also susceptible to the so-called "seating effect," so it should be brushed very gently to maintain its appearance.

Composition: 100% Polyester Weight: 290 g/m2 Roll width: 140cm Abrasion Resistance 90,000 Martindale cycles (BS EN ISO 12947-2:1998) Pilling: 4 (EN ISO 12 945-2) Light Fastness 5 (ISO 105-B02) Fastness to Rubbing Wet: 4-5 (UNI EN ISO 105-X12) Dry: 4-5 (UNI EN ISO 105-X12) Flammability: -DIN EN 1021-1

Charles fabric, due to its structure (long hair), can be arranged in a velour way while being used, creating the impression of different shades of upholstery. It is also susceptible to bending while sitting, which is why it should be combed very gently.

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Charles - Studio Design

Charles is an upholstery fabric with a velvety surface, featuring high abrasion resistance (90,000 Martindale cycles). It is available in a wide range of colors, from warm reds and browns to cool blues and greys.

Due to its structure (long pile), Charles may develop characteristic shading patterns during use, typical of velour fabrics, creating the appearance of varying tones in the upholstery. It is also susceptible to the so-called "seating effect," so it should be brushed very gently to maintain its appearance.

*Studio Design - Extended delivery time

Composition: 100% Polyester Weight: 290 g/m2 Roll width: 140cm Abrasion Resistance 90,000 Martindale cycles (BS EN ISO 12947-2:1998) Pilling: 4 (EN ISO 12 945-2) Light Fastness 5 (ISO 105-B02) Fastness to Rubbing Wet: 4-5 (UNI EN ISO 105-X12) Dry: 4-5 (UNI EN ISO 105-X12) Flammability: -DIN EN 1021-1

Charles fabric, due to its structure (long hair), can be arranged in a velour way while being used, creating the impression of different shades of upholstery. It is also susceptible to bending while sitting, which is why it should be combed very gently.

Studio Design - Extended delivery time

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

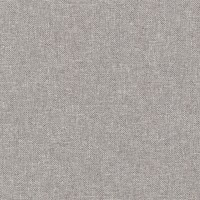

Cura

Cura is a versatile, two-tone upholstery fabric by Gabriel, made from 100% recycled polyester, which is itself recyclable. It holds the Oeko-Tex certification, confirming its safety.

The fabric features a matte, mélange texture that mimics the look of natural fibers, along with a trendy color palette characterized by subtle saturation and soft, blurred hues.

Composition: 98% recycled polyester, 2% polyester, Weight: 300 g/m² ± 5%, Abrasion resistance: 100,000 Martindale cycles (EN ISO 12947-2), Pilling: 4–5 (EN ISO 12945-2), Lightfastness: 5–8 (EN ISO 105-B02:2014)

Rubbing fastness: wet 4–5, dry 4–5 (EN ISO 105-X12), Flammability BS EN 1021-1, BS EN 1021-2, Certifications: EU Ecolabel, Oeko-Tex

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Era - Studio Design

This product by Camira is a polyester fabric featuring a mélange herringbone pattern and high abrasion resistance (100,000 Martindale cycles). The color palette includes both bright, cheerful tones and more subdued shades. Its matte texture and wide range of colors make it an appealing and versatile choice.

*Studio Design - Extended delivery time

Composition: Polyester 100%, Weight: 320g/m2 ±5%, Abrasion Resistance 100 000 Martindale cycles (EN ISO 12947:1998), Fastness to Rubbing 4 (ISO 105-X12:2002), Light Fastness 5 (EN ISO 105-B02:2014), Flammability (BS EN 1021-1 / BS EN 1021-2 / BS7176:2007 Low Hazard)

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Pastel

Flame-retardant base fabric made from Trevira CS yarn

A high-quality fabric made from original flame-retardant Trevira CS polyester yarn (100% polyester), meeting the highest fire safety standards. It is certified by Oeko-Tex, ensuring it is free from harmful substances and safe for use.

Available in a range of classic colours, the fabric offers exceptional durability – with an abrasion resistance of 70,000 Martindale cycles, it is a perfect choice for high-traffic commercial and public interiors.

Composition: Polyester 100%- TREVIRA CS,weight 260g/m2 +/-5%, abrasion 70 000 Martindale cycles, resistance to 5 (EN ISO 12945), light fastness 6 (EN ISO 105-B02), non-flammbility certificate (EN 1021-1, EN 1021-2; Crib 5; BS 7176 Medium Hazard;

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Roccia

Roccia is a fabric by Fidivi, made from original flame-retardant Trevira CS polyester yarn, ensuring the highest standards of fire resistance. It is Oeko-Tex certified, confirming its safety for human health. The fabric features a matte, natural-feeling surface. Available in a variety of appealing colors, it boasts high abrasion resistance (70,000 Martindale cycles) and excellent lightfastness.

100% polyester-TREVIRA CS weight 250g/m2 +/-5%, abrasion 70 000 Martindale cycles (UNI EN ISO 12947/2), resistance to pilling 5 (EN ISO 12945/2), light fastness 6 (EN ISO 105-B02),fastness to rubbing wet:4 (UNI EN ISO 105-X12) dry:5 (UNI EN ISO 105-X12), non-flammbility certificate: EN 1021-1:2006 EN 1021-2:2006

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Ally

A product by Svensson, made from Norwegian sheep wool blended with polyamide, combines raw Scandinavian design with a rich palette of mélange colors. Natural shades dominate, and when mixed with dyed fibers, they create a sense of depth in the texture. The diagonal weave highlights the refined character of the wool.

The fabric is highly abrasion-resistant and Oeko-Tex certified, making it suitable for a wide range of interior applications.

Composition 85% Wool, 15% Polyamid, Weight 320 g/m2 ± 5%, Abrasion resistance 100 000 Martindale cycles (EN ISO 12947-2), Light fastness 5-7 (EN ISO 105-B02), Fastness to rubbing Wet: 3-4 (EN ISO 105-X12), Dry: 4 (EN ISO 105-X12), Flammability • EN 1021-1 • EN 1021-2

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Ally-Studio Design

A product by Svensson, made from Norwegian sheep wool blended with polyamide, combines raw Scandinavian design with a rich palette of mélange colors. Natural shades dominate, and when mixed with dyed fibers, they create a sense of depth in the texture. The diagonal weave highlights the refined character of the wool.

The fabric is highly abrasion-resistant and Oeko-Tex certified, making it suitable for a wide range of interior applications.

*Studio Design - Extended delivery time

Composition 85% Wool, 15% Polyamid, Weight 320 g/m2 ± 5%, Abrasion resistance 100 000 Martindale cycles (EN ISO 12947-2), Light fastness 5-7 (EN ISO 105-B02), Fastness to rubbing Wet: 3-4 (EN ISO 105-X12), Dry: 4 (EN ISO 105-X12), Flammability • EN 1021-1 • EN 1021-2

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Alpa-Studio Design

Bouclé fabric with large, irregular loops, combining a distinctive texture with natural colors. Soft and pleasant to the touch, it creates a cozy atmosphere in interiors. It is Oeko-Tex certified, confirming its safety.

*Studio Design - Extended delivery time

Composition: 95% Polyester, 5% Acrylic, Weight 550 g/m2 ± 5%, Roll width 140 cm, Abrasion resistance >50 000 cykli Martindale’a (EN ISO 12947-2), Pilling 4 (UNI EN ISO 12945-2), Light fastness 4 (EN ISO 105-B02), Fastness to rubbing Wet: 4-5 (ISO 105-X12), Dry: 4-5 (ISO 105-X12)

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Blazer

This product from Camira is a fabric made of 100% premium-quality wool – durable and refined. It is produced through a process of weaving, felting, and surface raising. Naturally flame-retardant, it meets the cigarette and match ignition tests according to British standards.

It comes with a 10-year warranty and an abrasion resistance of 45,000 Martindale cycles.

Available in a wide palette of shades, ranging from natural beiges and browns to vibrant floral tones. Wool is naturally stain-resistant, repels water, and maintains its aesthetic appearance with proper care.

Virgin wool 100%, Weight 460g/m2 +/-5%, abrasion resistance 65 000 Martindale cycles, fastness to pilling 4 (BS:EN ISO 12945-2:2000), ligh fastness 5 (ISO 105-B02:1999); non-flammability certificate: BS EN 1021-1:2006, BS EN 1021-2:2006,

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Cura - Studio Design

Cura is a versatile, two-tone upholstery fabric by Gabriel, made from 100% recycled polyester, which is itself recyclable. It holds the Oeko-Tex certification, confirming its safety.

The fabric features a matte, mélange texture that mimics the look of natural fibers, along with a trendy color palette characterized by subtle saturation and soft, blurred hues.

*Studio Design - Extended delivery time

Composition: 98% recycled polyester, 2% polyester, Weight: 300 g/m² ± 5%, Abrasion resistance: 100,000 Martindale cycles (EN ISO 12947-2), Pilling: 4–5 (EN ISO 12945-2), Lightfastness: 5–8 (EN ISO 105-B02:2014)

Rubbing fastness: wet 4–5, dry 4–5 (EN ISO 105-X12), Flammability BS EN 1021-1, BS EN 1021-2, Certifications: EU Ecolabel, Oeko-Tex

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Cyber-Studio Design

Cyber is a fabric that catches the eye and sparks inspiration. Made from 100% recycled polyester, it combines environmental responsibility with modern design. Its multidimensional texture, matte finish, and subtle suede-like softness give interiors a warm, natural feel.

Unique, bold color combinations make Cyber a perfect fit for creative, flexible workspaces — where both aesthetics and functionality matter.

100% recycled polyester Möbelfakta certification – a guarantee of quality and responsible production

Studio Design – extended order lead time

Composition: 100% post-consumer recycled polyester, Weight: 407 g/m², Abrasion resistance: 120,000 Martindale cycles (EN ISO 12947)

Pilling resistance: 4–5 (EN ISO 12945-2) Lightfastness: 7–8 (ISO 105-B02) Color fastness to rubbing: Wet: 4–5 Dry: 4–5 (ISO 105-X12) Flame retardancy certification: BS EN 1021-1 & 2 (cigarette and match tests)

Certified: Oeko-Tex

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Easy - Studio Design

Easy is a beautiful, monochromatic upholstery fabric with a subtle diagonal weave structure, created by Svensson. Its rich, fruit- and flower-inspired colours highlight the natural beauty of wool.

Thanks to its high abrasion resistance and Oeko-Tex certification, the fabric is suitable for a wide range of interior applications. It is part of the Studio Design collection, which may result in extended lead times for orders.

*Studio Design - Extended delivery time

Composition: Wool 85% Polyamide 15%, weight: 330 g/m², abrasion resistance 150 000 Martindale cycles (EN ISO 12947-2), light fastness 5-7 (EN ISO 105-B02), fastness to rubbing wet:3-4, dry:4 (EN ISO 105-X12), flammability : EN 1021-1&2, BS 5852 crib 5, Oekotex

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Oceanic

Oceanic is a unique fabric by Camira, made entirely from recycled polyester, 50% of which is SEAQUAL® yarn derived from marine waste. It’s an eco-friendly choice for seat upholstery.

The fabric is Oeko-Tex certified, confirming its safety. With high abrasion resistance and a 10-year manufacturer’s warranty, it is an excellent sustainable option for your furniture.

Composition 100% post-consumer recycled polyester (including 50% Sequal yam), Weight 497 g/m2 ± 5%, Abrasion resistance 100 000 Martindale cycles (EN ISO 12947-2), Light fastness 4-5 (EN ISO 105-B02), Fastness to rubbing Wet: 4 (EN ISO 105-X12) Dry: 4 (ENbISO 105-X12), Flammability • BS EN 1021-1:2014 • BS EN 1021-2:2014 • BS 7176 (Low Hazard)

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Silvertex

Silvertex is an exceptionally durable textile material with a PVC coating, offered by Spradling, featuring the innovative PERMABLOK finish. This technology helps create a more hygienic environment by reducing the presence of bacteria, fungi, and mildew — particularly important in medical and hospitality settings.

The material is highly resistant to cracking, tearing, and loss of elasticity.

Available in a wide range of colours, its semi-matte surface, embossed with a fabric-like texture, makes it an outstanding choice for use in public interiors. Despite its high level of protection, lighter shades may be prone to staining due to colour migration from other textiles.

Surface-100% Vinyl, basic material - 100% Polyester Hi-Loft2, weight 685g/m2, abrasion 300 000 Martindale cycles (EN ISO 12947:1999 Part 2), light fastness >7, non-flammability certificate (BS EN 1021-1/2, EN 1021/2, EN 71-2,

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Silvertex - Studio Design

Silvertex is an exceptionally durable textile material with a PVC coating, offered by Spradling, featuring the innovative PERMABLOK finish. This technology helps create a more hygienic environment by reducing the presence of bacteria, fungi, and mildew — particularly important in medical and hospitality settings.

The material is highly resistant to cracking, tearing, and loss of elasticity.

Available in a wide range of colours, its semi-matte surface, embossed with a fabric-like texture, makes it an outstanding choice for use in public interiors. Despite its high level of protection, lighter shades may be prone to staining due to colour migration from other textiles.

*Studio Design - Extended delivery time

Surface-100% Vinyl, basic material - 100% Polyester Hi-Loft2, weight 685g/m2, abrasion 300 000 Martindale cycles (EN ISO 12947:1999 Part 2), light fastness >7, non-flammability certificate (BS EN 1021-1/2

Studio Design - Extended delivery time

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Synergy

Synergy is a fabric by Camira, made of 95% premium-quality sheep’s wool with the addition of polyamide. It is produced through weaving, gentle felting, and surface raising, which gives it a soft and refined texture.

Compared to other fibres, wool is exceptionally resistant to soiling, naturally repels water, and with proper care maintains stain resistance, helping it retain its aesthetic appearance for longer. It is a strong, versatile fibre that creates durable and elegant textiles.

Compostion:virgin wool 95%, polyamide 5%; Weight: 400g/m2 ±5% Abrasion Resistance > 100 000 Martindale cycles, Fastness to Rubbing: 4 (ISO 105-X12) Light Fastness: 5 (ISO 105-B02) Flammability: EN 1021-1&2 Cigarette & Match

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Synergy - Studio Design

Synergy is a fabric by Camira, made of 95% premium-quality sheep’s wool with the addition of polyamide. It is produced through weaving, gentle felting, and surface raising, which gives it a soft and refined texture.

Compared to other fibres, wool is exceptionally resistant to soiling, naturally repels water, and with proper care maintains stain resistance, helping it retain its aesthetic appearance for longer. It is a strong, versatile fibre that creates durable and elegant textiles.

*Studio Design - Extended delivery time

Compostion:virgin wool 95%, polyamide 5%; Weight: 400g/m2 ±5% Abrasion Resistance > 100 000 Martindale cycles, Fastness to Rubbing: 4 (ISO 105-X12) Light Fastness: 5 (ISO 105-B02) Flammability: EN 1021-1&2 Cigarette & Match

Studio Design - Extended delivery time

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Oceanic-Studio Design

Oceanic is a unique fabric by Camira, made entirely from recycled polyester, 50% of which is SEAQUAL® yarn derived from marine waste. It’s an eco-friendly choice for seat upholstery.

The fabric is Oeko-Tex certified, confirming its safety. With high abrasion resistance and a 10-year manufacturer’s warranty, it is an excellent sustainable option for your furniture.

*Studio Design - Extended delivery time

Composition: 100 % recycled polyester, weight 497g/m2 +/-5%, width 140cm, Abrasion resistance: ≥100 000 Martindale cycles, light fastness: 4/5 (EN ISO 105-B02), fastness to rubbing: wet: 4 (EN ISO 105-X12) dry:4 (EN ISO 105-X12) Flammability: EN 1021-1&2, BS 7176 Low Hazard; Oekotex

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Remix - Studio Design

This fabric is from Kvadrat, a company committed to quality and sourcing the finest yarns from New Zealand, Australia, the UK, and Norway. Wool is a natural, renewable material whose fibres have inherent flame resistance – it ignites at high temperatures and chars when exposed to fire, rather than melting or dripping.

Compared to other fibres, wool is especially resistant to soiling, naturally repels water, and with proper care maintains stain resistance, preserving its aesthetic appearance over time. It is a versatile, strong fibre that creates durable textiles which age gracefully.

The fabric is part of the Studio Design collection, which may result in extended lead times for orders.

*Studio Design - Extended delivery time

Composition: 90% wool, 10% nylon Weight: ok 300 g/m2 Abrasion Resistance: 100 000 Martindale cycles, Pilling: 3-4 (EN ISO 12945-2:2000) Light Fastness: 5-7 (ISO 105-B02:2000) Flammability: EN 1021 - 1/2 Producer: kvadrat Denmark

Studio Design - Extended delivery time

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Steelcut Trio 3-Studio Design

This fabric by Kvadrat places strong emphasis on quality and the origin of its yarns, sourced from New Zealand, Australia, the United Kingdom, and Norway. It is distinguished by exceptional durability and rich color depth. The innovative three-dimensional structure of the fabric creates an intriguing surface texture.

Its extensive color palette offers new possibilities for combining deep shades of red, purple, and green, as well as a variety of midtones that harmoniously blend vibrant floral hues with natural tones.

*Studio Design - Extended delivery time

Composition: 90% wool, 10% nylon; Abrasion Resistance 100 000 Martindale cycles; Fastness to Rubbing 3-4 (EN ISO 12945); Light Fastness: 5-7 (ISO 105-B02) Flammability: EN 1021-1/2; BS 5852 part 1

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Leather

Size Ca.5m2, thickness >0,8mm-1,1mm, wet rub tests>250 (BS EN ISO 11640: 1998) dry rub tests >500 (EN ISO 11640:1998) flex resistance > 50 000 cycles (BS EN ISO 5402:2002), PCP und CFC used during tanning proces, natural colour varations may occur, non-flammability certyficate (UNI EN 1021-1:2006, UNI EN 1021-2:2006)

Colors marked *available while supplies last

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

Metal - powder coated

The colours presented do not constitute an offer within the meaning of law. Materials are displayed for reference only and may vary by browser, monitor, or printer from the actual material colour. Before specifying, refer to a physical sample.

To download

Safety and compliance

Piece of furniture designed for seating. Meets the strength, safety and stability requirements specified in European standards.

Do not stand on the product, sit on the armrests (if the product has them) or the backrest, rock on the chair or perform other activities not related to the dedicated use of the product which may cause dangerous situations.

About collection

epocc

The Epocc chairs prove that design, like history, likes to come full circle. The minimalist design and the possibility of upholstering one chair in two different colours make it possible to create a modern piece of furniture with soul.

Design

Bejot Development Team

Our experienced R&D team creates original designs as well as collaborating with scientific institutions in the fields of acoustics, biophilia and workstation ergonomics. As a result, the team has unique know-how and takes a very responsible approach to the design process.

EN

EN

PL

PL

DE

DE

FR

FR